EXPERIENCE WITH PROCEDURES AND PROCEDURE MANAGEMENT SYSTEMS

- Managed and worked as a part of Tennessee Valley Authority (TVA’s) Central Staff specialists (1972 to 1988) responsible for welding, bolting, coatings, materials integrity, and associated compliance to codes and standards. This group had responsibility to resolve all the significant problems, facing TVA’s nuclear design, construction, and operation program to the satisfaction of TVA’s commitments to the Nuclear Regulatory Commission (NRC).

- Managed TVA’s Specification Improvement program. The program used 75 EBASCO subject matter specialists to develop an initial draft of the documents TVA wanted and about 34 different organizations had buy in to them prior to use. This program was required to be implemented after Three-Mile-Island caused Nuclear utilities in the United States to make changes in upper management.

- Developed numerous MI programs for operators, starting in the early 1990’s with the Rohm and Haas Deer Park program to develop MI and Maintenance procedures.

OUR SPECIALISTS & SAMPLE PROJECTS

Our specialists have the essential skills and professional training in the disciplines required to assess the root cause of the failure and its impact on the environment. A partial listing of some of the personnel on our team follows, (full resumes can be provided upon request).

AUGUSTUS’ “Senior Consultants” worked with the Chemical Manufacturer’s Association to develop CMA’s response to the Mechanical Integrity rule in 1992. CMA developed, what amounted to the only industry consensus interpretation of what OSHA intended when it published the Mechanical Integrity Rule documented in 10CFR 1910.119, subparagraph (j). That document, used to train over 300 of CMA’s member companies, can be used today as a cornerstone of a Compliance Program. A few years later our personnel implemented the first full refinery Risk Based Inspection Program at BHP Hawaii.

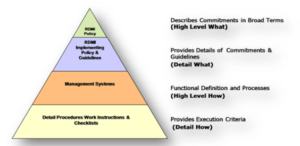

Our Quality Assurance program and consistent use of procedures and management systems ensures a work product that will meet or exceed contract expectations. The following provides an overview of some of the projects the company has executed since inception.

- 2014, for Major Chemical Plant – Texas, Developed Qualitative to Quantitative Risk Based Inspection Program for Pyrophoric Units, Risk Based Inspection Implementation Plan and External In-Lieu of Internal Inspection Audit and Improvement Options.

- 2013, for Major Pharmaceutical Plant – Virginia, Developed Risk Based Inspection Baseline Program Assessment, Inspection and Testing Procedures Manual, Risk Based Inspection Program Manual.

- 2012, for Commercial Gas Fractionation Plant – Texas, Completed Fitness for Service Evaluation in Lieu of Internal Entry for Ten Pressure Vessels Resulting in Documented Savings of $14,000,000 at total Plant Turnaround.

- 2012 for Commercial Gas Fractionation Plant Assisted with Heat Exchanger Failure Investigation, and Implementation of Risk Based Strategy for Testing Frequency of Safety Relief Valves.

- 2012, for NASA Stennis Air Force Base (as Subcontractor to Jacobs), Audited Facility Implementation of Risk Based Inspection Program and use of Lloyds Capstone RBMI Software.

- 2011, for Major Pipeline and Natural Gas Producer in Mid-America Developed Risk Based Mechanical Integrity and Inspection and Testing Procedures along with Document Management Program for Transition to New RBI Software.

- 2010, for 80K BPD Refinery in Kansas, Competed Risk Based Mechanical Integrity and Inspection Program, Including Implementation Procedures and Field Baseline Inspections.

- 2009, for Refinery in Kansas, Developed and Implemented Management System for Integration of Mechanical Integrity Assessment into the Process Hazard Analysis for the Plant.

- 2009, NASA Johnson Space Center, Updated Risk Based Inspection Analysis for Fixed Equipment at the Center, Ensured the Analysis Complied with Government Risk Analysis for Fixed Equipment.

- 2009, for Large Gas Fractionation Plant, Updated Existing Risk Based Inspection Program with Data Entry and Quality Control; Upgraded Plant Procedures to Present.

- 2007, for Large Refinery in the United States, Developed and Managed Plant-wide Quality. Control Program for Refinery That Ensured Leak Free Return to Service Following total Plant Turnaround, Involved over 500 Major Equipment Flange Joints.

- 2007, for One of the Largest Refineries in the United States, Conducted a Plant Specific Seminar on Bolted Flange Leak Reduction and Management for 20 Managers and Engineers.

- 2006, for Refinery in Kansas, Developed Turnaround Inspection Plans and Basis for Either Conducting or Deferring Inspections for about 300 Items With-out Plans Prior to Turnaround.

- 2004, for Fertilizer Plant, Developed Life Extension Plan for Boiler.

- 2005, for NASA Stennis Air Force Base (as Subcontractor to Jacobs), Trained Personnel in the Basics of How to Implement a Risk Based Inspection Program.

- 2003, For Major Refinery Customer, Conducted Fitness for Service Analysis Into Localized Thinning Of Heat Exchangers.

- 2006, Conducted Bolted Joint Leak Reduction Seminar for Thirty-five Experienced Managers and Engineers.

- 2004, for Four Offshore Deep-water Drilling Platforms, Developed Baseline Risk Based Inspection Program.

- 2004, for Major Deep-water Drilling Company, Conducted Failure Analysis and Investigation into Malfunction and of Structural Flange Joints on Deepwater Thruster Assemblies.

- 2004, for Major South American Customer Conducted Mechanical Integrity Training and Process Safety Training for Non-English Speaking Professionals.